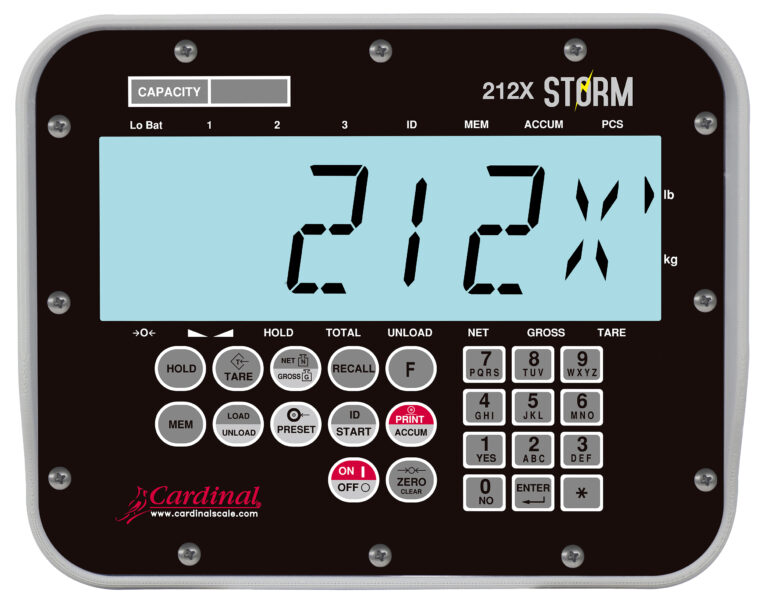

In industrial settings, precision is key to ensuring smooth operations, maintaining safety, and meeting production targets. Among the many factors that contribute to the reliability of industrial equipment, instrument calibration services play a crucial role. These services ensure that machinery and devices operate with optimal accuracy, directly impacting their efficiency, lifespan, and overall performance.

This article delves into how calibration services enhance the longevity of industrial equipment, helping businesses reduce downtime, cut costs, and improve operational reliability.

Why Calibration Services Matter for Industrial Equipment

Calibration is the process of adjusting and verifying the performance of instruments against standard measurements. Over time, environmental factors like temperature, humidity, and vibrations can cause equipment to drift from its original settings. If left unchecked, this drift can result in inaccurate readings, leading to faulty operations, product defects, and even equipment failure.

Instrument calibration services address these issues by recalibrating devices to their specified tolerances. Regular calibration ensures that your equipment operates at its peak efficiency, helping extend its service life.

Here are some key reasons why calibration services are vital:

Enhanced Accuracy

Properly calibrated instruments provide precise readings, reducing the risk of errors that could compromise operations or safety. Accurate equipment also means fewer repairs and replacements, contributing to long-term savings.

Compliance with Industry Standards

Many industries require equipment to meet strict regulatory and safety standards. Calibration services ensure that your machinery stays compliant, avoiding penalties and legal complications.

Optimized Performance

Calibrated equipment performs better, improving production efficiency and reducing wear and tear on mechanical components.

How Calibration Extends Equipment Longevity

The longevity of industrial equipment depends on multiple factors, including how well it’s maintained. Calibration plays a significant role in this process by addressing potential issues before they escalate.

Preventing Wear and Tear

When equipment operates with miscalibrated settings, it may exert unnecessary force or work harder than required, leading to premature wear and tear. Instrument calibration services ensure that each component functions within its designed parameters, minimizing strain and extending its lifespan.

Reducing Downtime

Unexpected equipment failures can halt production, resulting in costly downtime. Regular calibration services help identify and resolve potential issues early, ensuring uninterrupted operations.

Cost Savings Through Maintenance

Calibrating your instruments regularly is a proactive maintenance strategy. It’s far more cost-effective than reactive repairs or complete replacements of damaged equipment.

Enhancing Safety

Misaligned instruments can pose significant safety risks, especially in industries like manufacturing, healthcare, and energy. Calibration not only enhances safety but also boosts confidence in the reliability of your equipment.

Signs Your Equipment Needs Calibration

While many companies follow a routine calibration schedule, certain signs indicate that your equipment might need immediate attention:

Inconsistent Readings

If your instruments show fluctuating results, it’s a clear sign that calibration is needed.

Regulatory Audits or Compliance Checks

Prepare for audits by ensuring all equipment meets required calibration standards.

Environmental Changes

Exposure to extreme conditions can alter instrument accuracy, making calibration a priority.

Frequent Repairs

Equipment requiring repeated fixes may be suffering from calibration issues.

If you notice these signs, check over here for expert calibration services that can restore your equipment to optimal functionality.

Benefits of Partnering with Professional Calibration Services

Collaborating with a reputable service provider for your calibration needs ensures that your industrial equipment is in the best hands. Here’s why it matters:

- Expertise and Precision

Professional technicians use advanced tools and industry knowledge to deliver precise calibration results. - Tailored Solutions

Custom calibration plans are designed to suit your specific equipment and industry requirements. - Comprehensive Records

Accurate documentation provided by calibration experts helps with compliance, audits, and maintenance scheduling. - Long-Term Reliability

Regular professional calibration services enhance the durability of your equipment, improving ROI over time.

For more information on how to choose the right provider, you can find out more by researching companies with proven expertise in your industry.

Setting a Routine for Instrument Calibration

Developing a routine calibration schedule is crucial to maximizing the lifespan of your industrial equipment. Here are some tips to help you get started:

- Understand Manufacturer Guidelines

Follow the calibration intervals recommended by equipment manufacturers. - Track Usage Patterns

Instruments used more frequently or in harsh environments may require more frequent calibration. - Document Calibration History

Maintain a detailed log of all calibration activities for each piece of equipment. - Work with Trusted Providers

Regularly partner with professionals who offer instrument calibration services tailored to your operational needs.

If you’re unsure about the best calibration schedule for your equipment, you could check here for expert advice on creating a plan that works for your business.

Exploring Calibration Technology

The advancement of calibration technology has made the process faster and more accurate. Automated systems and digital tools now provide real-time calibration results, reducing downtime and improving reliability.

Additionally, remote calibration solutions allow technicians to access and adjust equipment without being on-site, saving time and costs. For businesses looking to modernize their maintenance strategies, go right here to learn about the latest innovations in calibration technology.

The Bottom Line

Investing in regular instrument calibration services is a smart move for any industrial business. Not only does it enhance equipment accuracy and reliability, but it also significantly extends the lifespan of your machinery. By reducing downtime, improving safety, and lowering maintenance costs, calibration services contribute to a more efficient and cost-effective operation. For those seeking to optimize their equipment longevity and ensure compliance with industry standards, find out how professional calibration services can transform your business. Take the proactive step today and Get More Information on partnering with experts who can help you achieve long-term success.