In the world of packaging, lamination plays a crucial role in determining not only the visual appeal but also the durability and functionality of the product. Two of the most common types of lamination used in packaging are matte and gloss finishes. Each brings its own set of advantages, offering businesses a chance to align their packaging design with brand identity, customer preferences, and product functionality.

In this article, we’ll explore matte vs. gloss lamination in detail, breaking down their properties, benefits, applications, and the factors to consider when deciding which lamination to choose for your packaging needs.

What is Lamination in Packaging?

Lamination is the process of applying a thin layer of plastic or film over a printed surface to enhance the packaging’s appearance, durability, and functionality. The lamination layer helps protect the print from scratches, moisture, and other external factors while giving it a polished look.

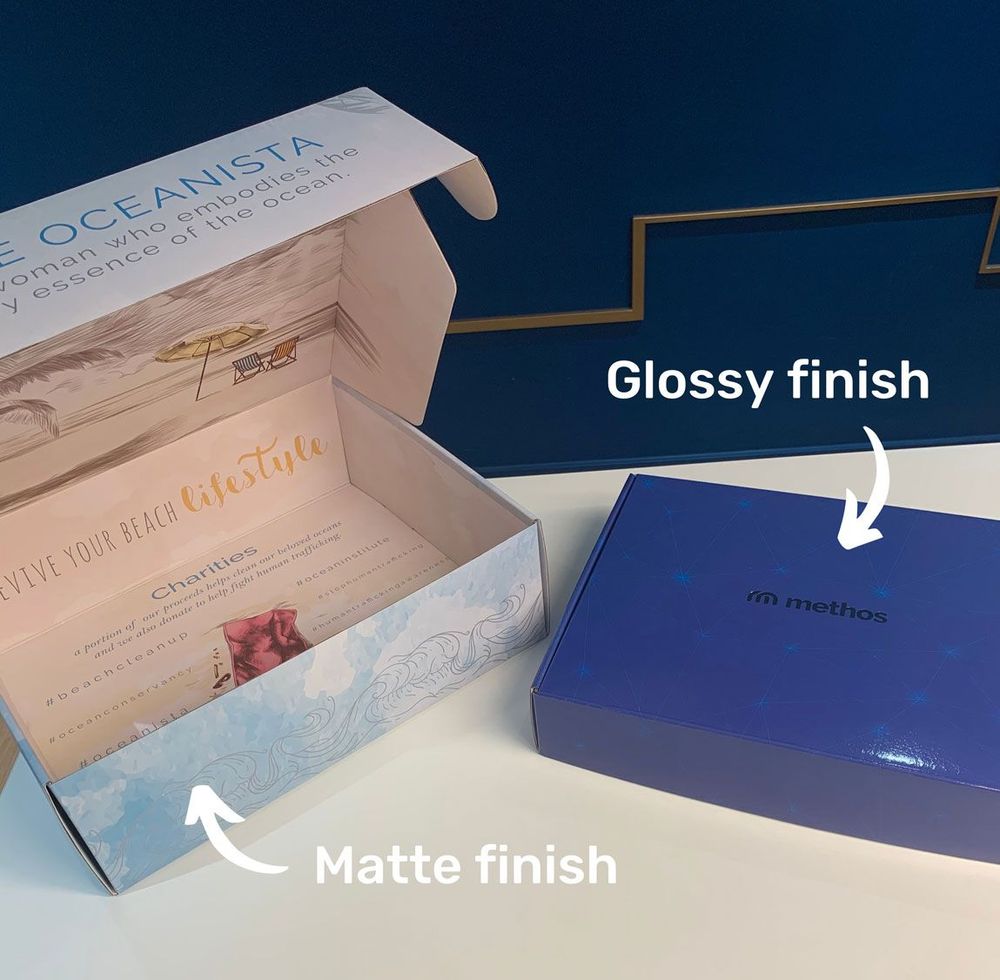

There are two main types of lamination:

Matte Lamination

A soft, non-reflective finish that gives a muted and subtle appearance.

Gloss Lamination

A shiny, reflective finish that enhances the vibrancy and clarity of colors.

Matte Lamination: A Subtle, Elegant Finish

Matte lamination is known for its understated and refined appearance. It adds a soft, velvety texture to the packaging, giving it a more premium and sophisticated feel. This type of lamination is often used for luxury brands, high-end products, or packaging where the focus is on subtle elegance rather than attention-grabbing shine.

Key Characteristics of Matte Lamination

Non-Reflective Surface

Matte lamination doesn’t reflect light, resulting in a smooth and soft look. This makes it easier to read the text on packaging and prevents glare.

Tactile Appeal

The soft-touch finish adds a sense of luxury to the packaging, offering a tactile experience that’s smooth and pleasant to touch.

Sophisticated Aesthetic

Matte finishes are often associated with premium and high-end products, making them ideal for luxury items, cosmetics, or electronics.

Scratch Resistance

Although matte lamination tends to show scratches and fingerprints more easily than gloss lamination, the finish itself is relatively resistant to scratches compared to uncoated packaging.

Pros of Matte Lamination

Elegance and Subtlety

Matte lamination creates a more restrained look, perfect for brands looking to communicate sophistication and elegance.

Ease of Reading

Without the glare that gloss finishes have, matte lamination ensures that the text and design elements are easily readable.

Reduced Glare

Perfect for packaging that will be displayed under bright lights, matte lamination reduces light reflection, making the design clearer.

Premium Texture

The velvety feel of matte lamination adds a layer of tactile luxury, which enhances the customer’s sensory experience.

Cons of Matte Lamination

Duller Colors

The muted appearance of matte lamination may not make the colors pop as vibrantly as gloss.

More Susceptible to Marks

Matte lamination can show fingerprints, smudges, and scratches more easily than gloss lamination.

Less Eye-Catching

Matte finishes can sometimes blend in, making it less noticeable on retail shelves compared to glossy packaging.

Applications of Matte Lamination

Matte lamination is ideal for industries where elegance and subtlety are important. Common applications include:

- Luxury product packaging

- Cosmetics and beauty packaging

- High-end electronics

- Premium food and beverage products

Gloss Lamination: A Vibrant, Eye-Catching Finish

In contrast to matte lamination, gloss lamination offers a shiny, reflective finish that enhances the vibrancy of colors and creates a high-impact look. This type of lamination is often used for packaging where the goal is to attract attention and create a sense of excitement or energy.

Key Characteristics of Gloss Lamination

High Shine and Reflectivity

The glossy surface reflects light, making the packaging stand out, especially under store lights.

Enhanced Color Vibrancy

Gloss lamination makes colors look richer and more vibrant, helping designs pop and become more eye-catching.

Smooth Texture

The surface of gloss lamination feels smooth and sleek, giving the packaging a polished, professional look.

Durability

Gloss lamination is highly durable, offering protection against scratches, moisture, and wear.

Pros of Gloss Lamination

Eye-Catching Appeal

Gloss lamination is designed to grab attention, making it perfect for products that need to stand out on the shelf.

Enhanced Colors

The shiny surface makes colors appear brighter, sharper, and more vibrant, which can be an advantage for designs with bold graphics or photographs.

Durability and Protection

Gloss lamination adds a durable layer of protection against external factors like moisture, scratches, and dirt.

Sleek and Modern Look

The reflective nature of gloss gives packaging a clean, contemporary look that appeals to a broad audience.

Cons of Gloss Lamination

Reflective Surface

The shiny surface can cause glare, making text and design elements harder to read in certain lighting conditions.

Fingerprints and Smudges

Gloss lamination tends to show fingerprints and smudges more easily than matte finishes, which can affect its appearance over time.

Less Premium Feel

While gloss lamination offers a vibrant and energetic look, it may not be suitable for brands aiming for a luxurious, high-end image.

Applications of Gloss Lamination

Gloss lamination works best for products that need to stand out on store shelves. It’s commonly used for:

- Food and beverage packaging

- Retail packaging

- Marketing materials like brochures and flyers

- Consumer goods and promotional items

Matte vs. Gloss: Factors to Consider for Packaging

When deciding between matte and gloss lamination for your packaging, consider the following factors:

Brand Identity

Your packaging is an extension of your brand, and the type of lamination you choose should align with your brand’s image. For a luxury or high-end brand, matte lamination may be the better option due to its sophisticated, subtle appeal. On the other hand, if your brand is energetic and bold, gloss lamination’s vibrant, eye-catching finish could be a better fit.

Target Audience

Understanding your target audience is crucial in deciding the type of finish. A youthful, vibrant audience may respond better to glossy packaging, while a more mature or luxury-focused audience might prefer the understated elegance of matte lamination.

Product Type

The type of product you’re packaging will also influence your choice of lamination. For example, high-end electronics, cosmetics, and luxury goods may be better suited to matte lamination, while vibrant, colorful products like toys, food items, or retail goods may benefit from the attention-grabbing effect of gloss lamination.

Durability Needs

Both matte and gloss lamination offer protection, but gloss lamination tends to be more durable when it comes to resisting scratches, moisture, and general wear and tear. If your packaging needs to endure tough conditions, gloss might be a better choice.

Visual Impact

If you want your packaging to pop on the shelf, gloss lamination’s high-shine, vibrant effect might be the way to go. However, if you’re aiming for a more refined and sophisticated look, matte lamination will give you the desired effect without overpowering the design.

Conclusion

Choosing between matte and gloss lamination comes down to understanding your brand, your audience, and your product’s needs. Matte lamination offers a subtle, elegant look that appeals to luxury brands, while gloss lamination delivers a vibrant, eye-catching finish that can help products stand out on crowded shelves.

Ultimately, both matte and gloss lamination have their place in the packaging industry, and your decision should be guided by how you want your product to be perceived and the kind of experience you want to offer your customers.

Whether you go for the luxurious matte or the energetic gloss, the right lamination will elevate your packaging and enhance the overall appeal of your product.