Introduction

Chloroquine phosphate is a widely used medication primarily known for its effectiveness in treating malaria. Initially introduced as a treatment for malaria, chloroquine has gained attention for its potential role in treating various autoimmune diseases, such as rheumatoid arthritis and lupus. The growing demand for chloroquine phosphate, particularly during health crises like the COVID-19 pandemic, highlights the need for a robust manufacturing infrastructure. This Chloroquine Phosphate Manufacturing Plant Project Report provides a comprehensive overview of setting up a Chloroquine Phosphate Manufacturing Plant, including market demand, production processes, investment requirements, and operational considerations.

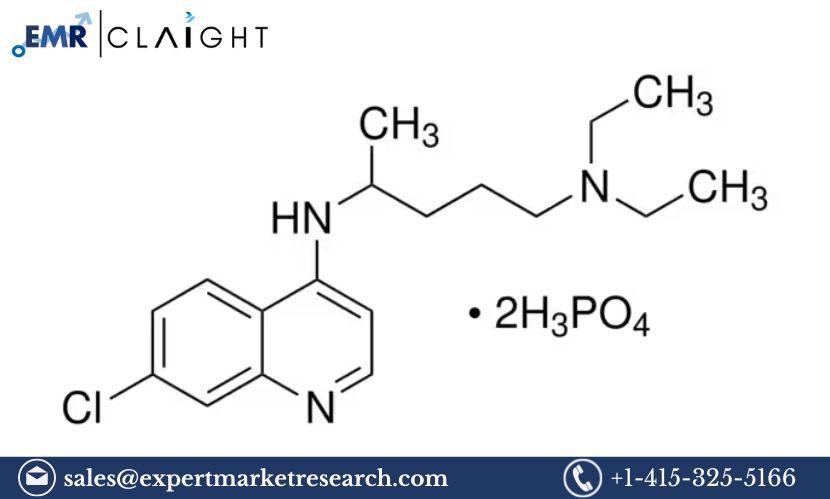

Understanding Chloroquine Phosphate

Chloroquine phosphate is a synthetic organic compound derived from quinine, a natural compound extracted from the bark of the cinchona tree. It works by interfering with the growth of parasites in the red blood cells of the human body. In addition to its antimalarial properties, chloroquine is recognized for its immunomodulatory effects, which have opened new avenues for treatment in autoimmune diseases.

Market Demand for Chloroquine Phosphate

The global demand for chloroquine phosphate is influenced by several factors:

- Increase in Malaria Cases: Malaria remains a significant public health issue in many tropical and subtropical regions. The World Health Organization (WHO) continues to emphasize the importance of effective malaria treatments, ensuring sustained demand for chloroquine.

- COVID-19 Pandemic: The outbreak of COVID-19 brought chloroquine into the spotlight as a potential treatment option, leading to a surge in demand. Although further studies are needed to confirm its efficacy against COVID-19, this has contributed to increased interest in its production.

- Rising Prevalence of Autoimmune Diseases: The increasing incidence of autoimmune diseases, such as rheumatoid arthritis and lupus, has also boosted the demand for chloroquine phosphate as a therapeutic option.

- Emerging Markets: With rising healthcare awareness and improved access to medicines, countries in Africa, Asia, and Latin America are witnessing increased demand for antimalarial drugs, including chloroquine.

Get a Free Sample Report with Table of Contents @

Benefits of Setting Up a Chloroquine Phosphate Manufacturing Plant

- Growing Market: With an increasing demand for chloroquine phosphate driven by various health concerns, establishing a manufacturing plant presents a lucrative opportunity.

- Diverse Applications: Besides treating malaria, chloroquine’s potential applications in autoimmune diseases provide additional market avenues.

- Favorable Profit Margins: The pharmaceutical industry generally offers attractive profit margins, especially for essential medicines.

- Export Opportunities: With the rising global demand for chloroquine, there is potential for export to markets with limited local production capabilities.

- Research and Development: The continuous research surrounding chloroquine and its derivatives can lead to the development of new formulations and products.

Raw Materials Required for Chloroquine Phosphate Production

The primary raw materials required for producing chloroquine phosphate include:

- 4-Aminoquinoline Derivatives: These are essential precursors in the synthesis of chloroquine.

- Phosphoric Acid: Used in the production process to create chloroquine phosphate.

- Other Chemicals: Solvents and reagents required for the synthesis process, such as acetone, ethanol, and hydrochloric acid.

Manufacturing Process of Chloroquine Phosphate

The manufacturing process for chloroquine phosphate involves several key steps:

- Synthesis of 4-Aminoquinoline Derivatives: The process begins with the synthesis of 4-aminoquinoline compounds from aniline and other chemicals.

- Formation of Chloroquine: The synthesized derivatives are then reacted with other reagents, typically involving phosphoric acid, to form chloroquine.

- Crystallization: The chloroquine solution undergoes crystallization to produce chloroquine phosphate. This step is critical for ensuring the purity and quality of the final product.

- Purification: The crystals are purified through recrystallization to remove any impurities, ensuring that the final product meets pharmaceutical quality standards.

- Drying and Milling: The purified crystals are dried to remove moisture and milled to achieve the desired particle size for formulation.

- Quality Control: Rigorous quality control measures are implemented throughout the production process to ensure compliance with regulatory standards.

Machinery Required for Chloroquine Phosphate Production

Establishing a chloroquine phosphate manufacturing plant necessitates specialized machinery and equipment, including:

- Reactor Vessels: For the chemical reactions involved in synthesizing chloroquine.

- Crystallizers: For the crystallization process to obtain chloroquine phosphate.

- Filtration Units: To separate impurities during the purification stage.

- Dryers: For removing moisture from the final product.

- Milling Equipment: For achieving the desired particle size of chloroquine phosphate.

- Quality Control Lab Equipment: For testing and ensuring the quality and purity of the product.

Financial Considerations: Investment and Profitability

Setting up a Chloroquine Phosphate Manufacturing Plant involves careful financial planning. Key components of the investment include:

- Initial Capital Investment: The total investment can range from $1 million to $5 million, depending on the scale of production, location, and technology.

- Operating Costs: Ongoing expenses such as raw materials, labor, utilities, maintenance, and regulatory compliance must be considered in the overall cost structure.

- Profit Margins: Chloroquine phosphate manufacturing typically offers profit margins ranging from 20% to 30%, depending on production efficiency and market conditions.

- Return on Investment (ROI): Given the growing demand for chloroquine phosphate, the ROI can be favorable, especially if the plant operates at optimal efficiency.

Market Potential and Target Industries

The chloroquine phosphate market serves a variety of industries, including:

- Pharmaceuticals: The primary application of chloroquine phosphate is in the pharmaceutical industry for treating malaria and autoimmune diseases.

- Public Health: Governments and health organizations rely on chloroquine for malaria treatment and control programs.

- Research Institutions: Research labs and institutions study chloroquine for its potential applications in other therapeutic areas.

- International Health Organizations: Organizations such as the WHO and NGOs involved in disease eradication efforts utilize chloroquine in their initiatives.

Regulatory Considerations

Compliance with health and safety regulations is critical for operating a chloroquine phosphate manufacturing plant. Key regulatory aspects include:

- Good Manufacturing Practices (GMP): Adhering to GMP standards ensures the production of safe and effective pharmaceutical products.

- Environmental Regulations: Compliance with environmental laws regarding emissions, waste management, and chemical handling is crucial.

- Quality Standards: Meeting industry standards for product quality, such as those set by the FDA or EMA, is necessary for regulatory approval and market access.

FAQs

- What is chloroquine phosphate used for?Chloroquine phosphate is primarily used to treat malaria and is also effective for certain autoimmune diseases.

- How is chloroquine phosphate produced?Chloroquine phosphate is produced through the synthesis of 4-aminoquinoline derivatives, followed by a series of chemical reactions and crystallization.

- What raw materials are needed for production?The main raw materials include 4-aminoquinoline derivatives and phosphoric acid, along with other solvents and reagents.

- What is the investment required to set up a chloroquine phosphate manufacturing plant?Initial investments typically range from $1 million to $5 million, depending on the scale and location of the plant.

- What are the profit margins in chloroquine phosphate manufacturing?Profit margins generally range from 20% to 30%, depending on production efficiency and market demand.

Related Reports

https://www.expertmarketresearch.com/reports/incident-and-emergency-management-market

https://www.expertmarketresearch.com/articles/top-digital-marketing-companies

https://www.expertmarketresearch.com/reports/plastic-additives-market

Media Contact:

Company Name: Claight Corporation

Contact Person: Lewis Fernandas, Corporate Sales Specialist — U.S.A.

Email: sales@expertmarketresearch.com

Toll Free Number: +1–415–325–5166 | +44–702–402–5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Website: www.expertmarketresearch.com

Aus Site: https://www.expertmarketresearch.com.au